We provide switch components and decorative components for automotive-related products.We realizes processing according to customer's request by high dimensional accuracy, special metal molds,stable quality control and production process by CPK management.

Fukushima factory

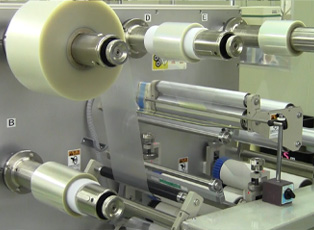

"With a focus on stamping technology, we have provided processed products of a wide variety of sheet materials, tapes and other by leveraging the strengths of the commercial sector.

We aim to be the customer's best with various capabilities such as processing of optical equipment components, decorative components, switch components, heat dissipating components, and functional sheet materials, as well as bonding and assembling."

- 4,888 days continued without accidents that require time off from work

- From January 1, 2003 to March 31, 2021, 4,888 days continued without accidents that require time off from work.

Product field

We provide processed products of adhesive tapes and processed optical sheets, mainly for display panel products that are indispensable for mobile terminals.We meet the high quality requirements of precision equipment parts with clean environment and laminating technology.

We offer a wide range of products in a wide range of fields, utilizing the material proposal network of trading company functions. In addition, we respond meticulously to the changing needs of our customers, including proposals for domestic and overseas cooperating partners.

Processing Technology

Slit

Stamping

Laminate

- Long term

- By improving manufacturing methods and material efficiency repeatedly, we provide long-run products for more than 20 years.

- Composite

- In addition to stamped products, we also offer composite products that are made by assembling with other components.

- Optimal

- In addition to our factory-processed products, we offer optimal products that incorporate customer manufacturing processes.

- Improvement

- We offer products with improved reliability by high-temperature and high-pressure processing in addition to normal bonding processing.

Quality control

We have obtained ISO9001 and ISO14001 certifications for quality and environmental management.And having received guidance from automotive-related partners, we have been promoting the construction of a production management system based on the TPS (Toyota Production System) since 2008.In order to meet further needs, we are working on acquiring IATF16949 certification, an international quality management standard for the automotive industry.(Scheduled to obtain on May, 2020)

Shimoda Kogyo Ibaraki

We have a history of 60 years as a factory centering on vacuum forming technology. Our integrated system is our strength, and we handle everything from material procurement, sheet extrusion, molding to shipping. We will continue to refine our processing technology as a company that meets the needs of customers ranging from small products to large products, thin products to thick products, such as in-vehicle decoration, various equipment covers, one-piece molding of artificial marble, and food trays.

- Location/Contact

- ●Location: 16-16 Minamimachi Gakuen Ibaraki-city Osaka 567-0834 ● (072)634-1551

Processing technology

Main manufacturing item

- Decorative panel for vehicle

- Industrial equipment covers

- Commercial refrigerator parts

- Vanity mirror cabinet

- Unit bath (apron)

- Artificial marble

- Food tray

Processing technology

- Vacuum forming

- Pressure forming

- TOM molding (3D coated molding)

- Top plate integral molding of artificial marble

- Sheeting

- Press working

- NC router processing

- Laser processing

Equipment

- Vacuum molding machine

(maximum molding size):

1,600mm x 2,800mm - Air pressure molding machine

(maximum molding size):

1,500mm x 2,200mm - TOM molding machine

(maximum molding size):

550mm x 1,250mm - Artificial marble molding machine

(maximum molding size) :

Top plate W750mm x W1,800mm - Sheet extruder

- Press machine

- NC router machine

- Laser processing machine

- 3D CAD

- 3-3-6 Utajima Nishiyodogawa-ku Osaka-city Osaka 555-0021

- PH +81 6-6472-1541

FAX +8106-6473-2455